RADIANT FLOOR SOLUTIONS Distribution Manifold

RADIANT FLOOR SOLUTIONS Distribution Manifold

The RADIANT FLOOR SOLUTIONS distribution manifold is designed to offer a simple method of distributing any form of heating, cooling or domestic piped service from a single source. The manifold is based around a simple one piece stainless steel extrusion to which a number of different accessories can be fitted for different types and sizes of plastic and copper pipes.

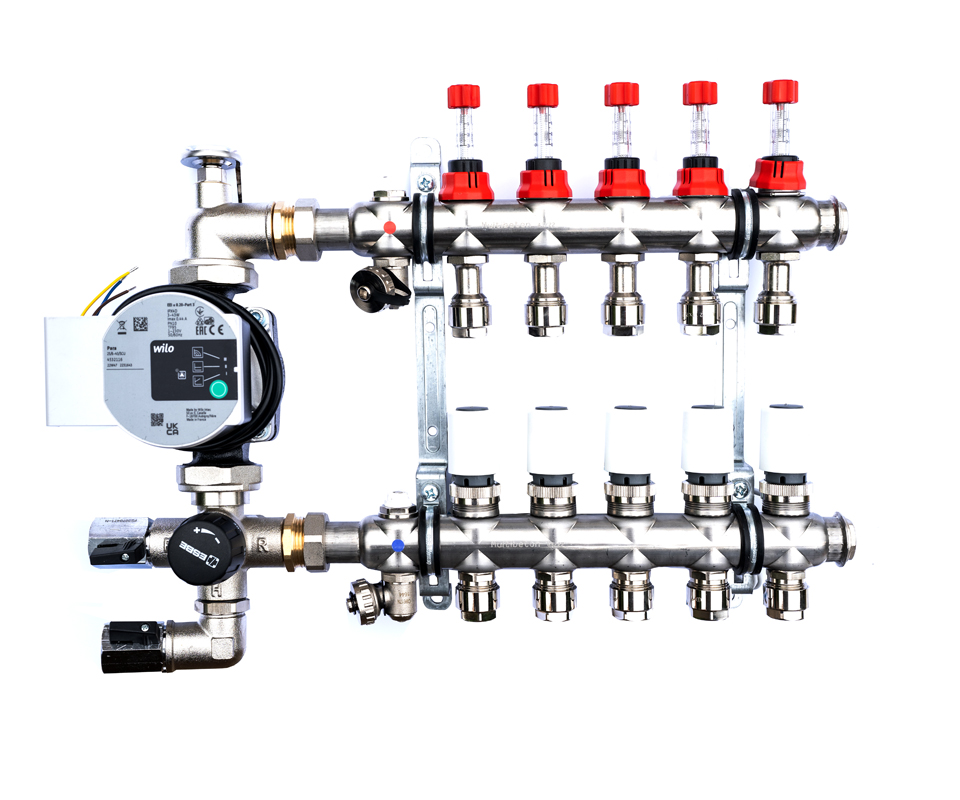

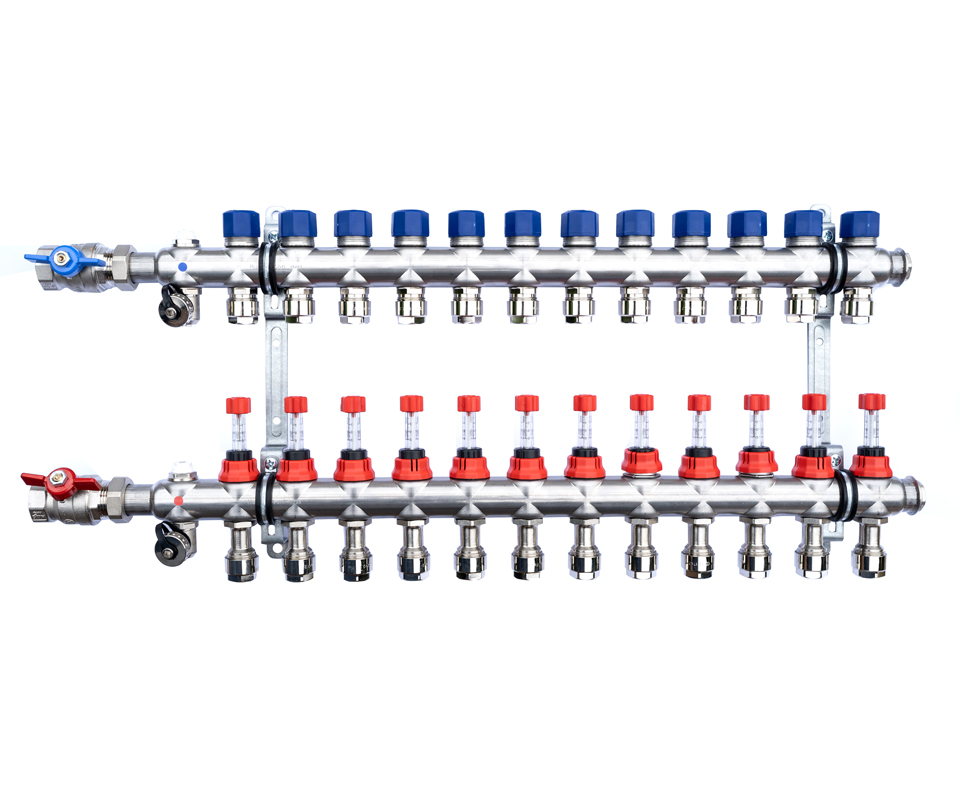

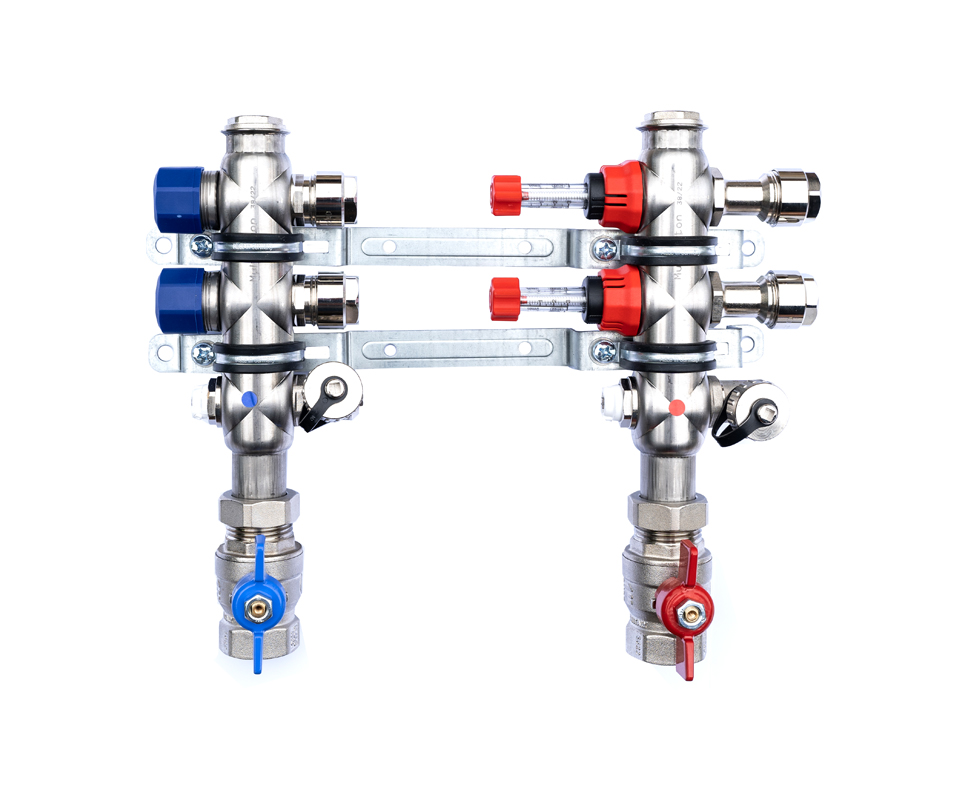

The illustration left shows a standard arrangement suitable for heating or cooling with individual valves for each circuit. The flow valve incorporates a pre-setting device to enable the flow rate to be permanently set whilst the return can be fitted with an isolation valve or visual Taco meter calibrated in litres per min.

The individual sections ensure there is no cross heat transfer between flow and return. In addition the main flow and return connections can be fitted with individual flow and return thermometers, binder test points and isolating valves.

The manifold can be mounted in any attitude and if required any individual connection can be reversed on site to discharge in the opposite direction.

All materials used are designed to be non-corrosive and can be used on all types of systems up to an operating pressure of 6 Bar.

In addition to the above a whole range of additional fittings can be provided including electric actuators both 24 or 240 volts.

The compact size of the manifold enables easy surface mounting or installation within the depth of a standard wall. In addition a cabinet can be provided suitable for surface or recess mounting (see separate data sheet).

The most common application is for use with our range of floor wall and ceiling heating and cooling systems but the distribution manifold can be used to equal effect on fan coils, radiators, convectors and other similar type of equipment. The ease with which circuits can be balanced, controlled or isolated at a single source limits their use only to your imagination.

Manifolds from 2 to 12 circuits can be supplied as one piece but by use of connecting nipples any length can be assembled on site up to the flow capacity of the 1¼” internal dia of the extrusion. All individual valves are pre-assembled onto the manifold and site fixing only entails locating and fixing to the mounting brackets. Other additional accessories are supplied loose for on site fixing enabling items such as thermometers and electric actuators to be left off until required.

Complete Manifold assembly as Follows: Flow & Return extrusions 1” internal diameter Flow & return valves End plugs, manual air vents & draincocks Mounting Brackets as schedule below

Part N° | Circuits | Brackets | Length L in mm |

60217 | 2 | 2 | 160 |

60317 | 3 | 2 | 210 |

60417 | 4 | 2 | 260 |

60517 | 5 | 2 | 310 |

60617 | 6 | 2 | 360 |

60717 | 7 | 2 | 410 |

60817 | 8 | 2 | 460 |

60917 | 9 | 2 | 510 |

61017 | 10 | 2 | 560 |

61117 | 11 | 2 | 610 |

61217 | 12 | 2 | 660 |

Copyright Radiant © 2026. All rights reserved