Radiant Floor Solutions Pipes in Screeds & Concrete Floors

Radiant Floor Solutions Pipes in Screeds & Concrete Floors

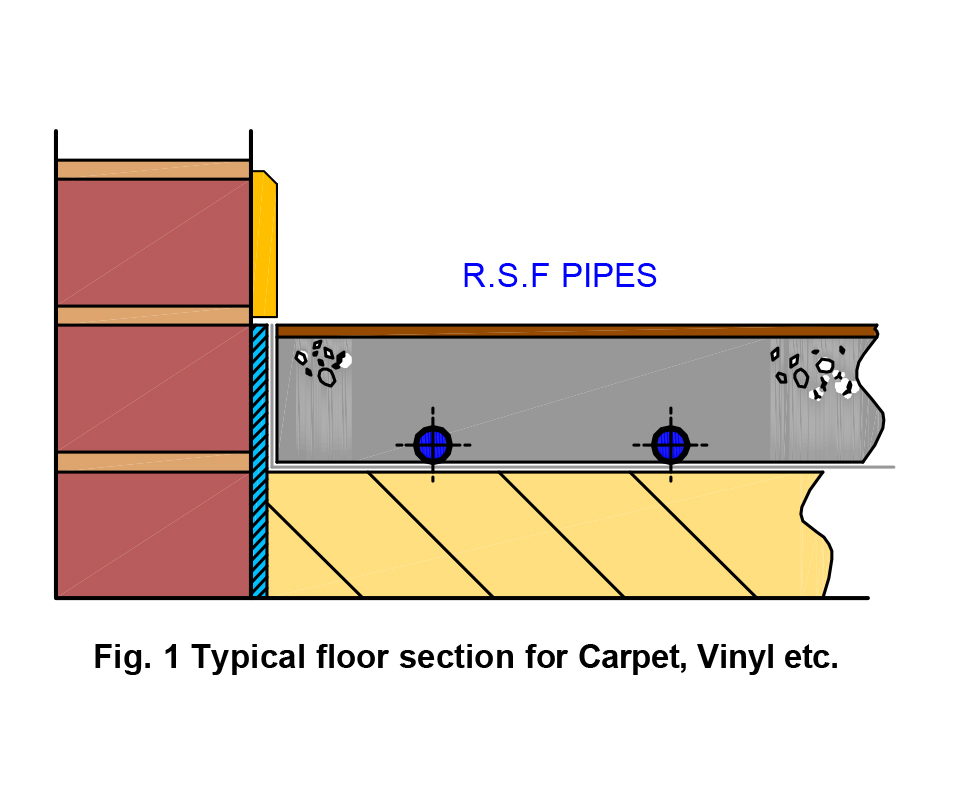

Most RADIANT FLOOR SOLUTIONS installations are installed above a layer of sub floor insulation and for this reason the floor screed or concrete should always be regarded as floating, ie de-bonded from the structure.

To comply with BS 8204-1:2003 the floating floor screed should be a minimum of 65-70mm for light traffic use and at least 75mm for most other types of floor. This excludes specialised types of floor using special mixes which should be treated separately.

The installation of a RADIANT FLOOR SOLUTIONS system does not in any way

affect the design or quality of the floor which providing the relevant standards are complied with will give the same standards as any other floating floor.

With floating floor construction the risk of curling is higher than with bonded floors and for this reason care needs to be exercised in the specification and laying of these types of floors.

Generally the thicker the floating floor the less risk there will be of curling although of more significance will be the type of mix used, water content and the degree of care used in curing the finished floor. The use of fine concrete and steel reinforcement as recommended by the above British Standard can reduce the risk that may apply but there can be no final substitute for good workmanship.

Materials

The materials used for standard concrete and screed floors should comply with the following. Cement: The cement should at the time of use comply with BS EN 197-1:2000

Aggregate

The water used for mixing should comply with appendix A of BS EN 1008:2002

Water

Any admixtures used should be as per manufacturers instruction and or comply with BS EN 934-3:2003

Admixtures

Any admixtures used should be as per manufacturers instruction and or comply with BS EN 934-3:2003

Reinforcement

The reinforcement if required should consist of polyproplene fibres or mesh to comply with BS 4483: 1998

General

The specification for the floor will depend on the structural qualities required and the use of such floors. Of equal importance is the type of floor finish and generally fine concrete and screeds should not be considered suitable as a wearing surface unless specially finished.

Generally lighter floor finishes such as carpet and vinyl will require a more substantial base than heavier finishes such as stone slabs etc.

The following table can be used for selecting the type of floor and thickness required but in all cases this should be checked with the requirements of the structural engineer and or architect.

In all the above cases a higher specification can always be used and reinforcement by use of steel mesh will enhance the characteristics of the floor and reduce the risk of cracking.

Above 15 kN the floor should be designed as a structural slab with a minimum overall depth of 100mm with reinforcement.

Reinforcements

The use of steel reinforcements in both cement/sand screeds and fine concrete when constructing floating floors is desirable. For floors with loadings of 5kN and above reinforcement should always be included in the form of polyproplene fibres or mesh.

Selection of the appropriate reinforcement will depend on a number of factors such as type of mix and method of mixing, floor loadings and depth. The use of reinforcement will reduce the risk of cracking and enhance the compression and flextural strength of the floor. In the absence of specific recommendation from the structural engineer or architect the following will be suitable for most applications.

In the case of polyproplene fibres these can be added direct to the mixer when batching the materials on site or in the case of ready mixed fine concrete it should be added on arrival prior to discharge. This has a much reduced labour cost compared with the laying of steel mesh and minimises risk of damage to the floor insulation. When using steel fabric reinforcement this should be laid above the RADIANT FLOOR SOLUTIONS pipework and overlapped at by at least one full mesh and wire tied together where movement is likely.

Tolerances on level and surface

The required tolerance to the finished floor will depend on the final floor finishes and use of the floor but in either case is not affected by the inclusion of a RADIANT FLOOR SOLUTIONS system. For most types of floor class SR2 (BS 8204-2:2003) will be quite suitable for use with most final floor finishes. If a higher standard is required then this must be specified at the design stage. Where the final floor finish is to be a stone floor or similar over the screed or concrete where the surface regularity is not critical then class SR3 may be acceptable in most cases.

Movement joints

Due to the separation between structural slab and a floating floor it is not always necessary to mirror any movement joints within the screed. Joints where required need not coincide provided any design movement can be absorbed by the layer of insulation.

If movement or construction joints in the floating floor are required to coincide with joints in the slab then these should be determined in advance and a day joint formed. This can have an additional flexible joint inserted if required. It is not necessary for the flexible joint to extend all around all the RADIANT FLOOR SOLUTIONS pipe and provided the flexible joint extends from the top of the pipes to the screed surface then the portion of screed below will crack naturally.

Generally the RADIANT FLOOR SOLUTIONS pipes will have been designed not to cross main construction joints if at all possible. If it has been necessary to cross such a joint the pipes will have been sleeved prior to screeding. No special precautions need be taken with RADIANT FLOOR SOLUTIONS pipes crossing normal day joints in screed and concrete floors.

When constructing concrete floor slabs in large areas with post cutting of joints by saw then sufficient cover over the pipe must exist to allow for the depth of cut required. In such cases it would be normal practice for the pipe to be in the bottom portion of the slab.

Where it is intended to install specialized joints for floor finishes such as terrazzo and marble extending through the screed and finished floor then consultation for the overall design should take place with RADIANT FLOOR SOLUTIONS prior to installation.

Structural Concrete Floors

RADIANT FLOOR SOLUTIONS pipes are well suited to installation in structural concrete floors from 100 to 300mm in depth. In most of these cases the floor will have been designed to suit the structural requirements for both the concrete used and the degree of reinforcement.

There are no changes or special requirements for the inclusion of RADIANT FLOOR SOLUTIONS pipes within a structural slab and the characteristics of the floor will not be affected in any way. For these types of floor the pipes will normally be fixed to the bottom layer of steel reinforcement if used or laid on the oversite using the RADIANT FLOOR SOLUTIONS cliprail.

The concrete can be to the structural engineers requirements and requires no modifications for use with RADIANT FLOOR SOLUTIONS systems. The pipe is mechanically strong enough to withstand all normal site traffic and the absence of any joints in the pipe ensures that the concrete floor can be laid without concern for any leaks.

Curing of Screeds and fine Concrete

Screeds and fine concrete should be covered with waterproof sheeting for a period of at least 7 days or until such time that the floor has reached sufficient strength to resist curling and cracking. Particular care needs to be taken to ensure that the floor is not subjected to severe exposure by direct sunlight or forced drying. During this period traffic should be avoided over the floor and where the floor is a finished floor surface it may require more substantial protection throughout the remaining building

operations by use of boarding or other similar materials.

The floor is unlikely to reach full strength for a period of at least 28 days dependant on the depth and type of mix used. During this period the RADIANT FLOOR SOLUTIONS underfloor heating system should not be used for forced drying or curing. Information on the commissioning of RADIANT FLOOR SOLUTIONS systems is given on a separate data sheet which should be studied before heat is applied to the floor.

Copyright Radiant © 2026. All rights reserved